Introduction

The current challenges faced by the smart manufacturing industry include the management of rising expenses in extreme precision and complexity, as well as the enforcement of compliance from prototype development to mass production in the aviation and healthcare industry, which are highly regulative in nature. These issues are also made worse by the fragmented supply chain, with prototype creation and production outsourced to multiple suppliers. In this article, an overall strategy involving Precision CNC Machining with digital process management will be examined as an effective approach toward smoother transitions, better cost management, and supply chain robustness with extreme precision.

Why cost overruns and compliance gaps are the largest hidden risks in Smart Manufacturing?

The Achilles’ Heel of Modern Manufacturing

According to reports from organizations such as the McKinsey Global Institute, an area that is identified as highly problematic is the supply chain, and this directly affects the efficiency of Smart Manufacturing and Supply Chain Resilience. In cases where stages of product development are isolated, this results in an interrupted digital thread and hidden dangers that may threaten the viability and profitability of projects.

The Prototype-to-Production

One of the primary drivers of cost overruns is the mismatch between designs and manufacturing. If CNC prototyping services are adopted in a design without the consideration of Design for Manufacturability in volume production, the design could involve costly secondary operations or redesign.

- The Domino Effect of Poor DFM

A prototype may include shapes that take longer to machine or require special machine tools. If the design is passed on to a volume production house in that condition, the machining loops become inefficient with increased scrap rates and higher costs per unit, resulting in the profitability of the product melting away.

- Hidden Costs Associated with Data Handoffs

With each change from supplier to supplier, there could be risks of mistakes when the information is translated. There may be discrepancies when the information from the CAD files is interpreted, and also when the key information regarding the machining of the parts may be overlooked.

The Compliance Nightmare of Supplier Qualification

Industries such as the aerospace and healthcare industries do not have “compliance” as an end point, “compliance” being an ongoing process. Without critical prototyping certifications such as AS9100D and ISO 13485, the entire product development cycle can impact the final product. The prototype developed would not comply with the required quality management systems, and this would result in re-validations by the production company, leading to significant costs and also damaging “time to market.”

In What Ways Can a Prototyping-to-Manufacturing Integrated Strategy Facilitate Seamless Transitions?

Figure 2: The Integrated Manufacturing Digital Thread: Seamless data flow from design to production ensures consistency, traceability, and cost control.

The Power of a Unified Manufacturing Model

The answer is to go with an Integrated Manufacturing solution. By combining prototyping, pilot production, and production with a single partner that is fully accredited, these pain points associated with multiple handoffs can be easily eradicated. This also ensures consistency with respect to technical communication, quality, and program management.

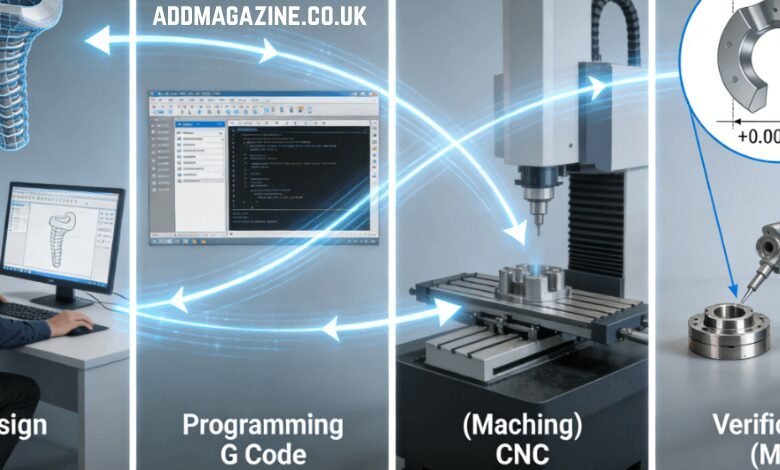

The Digital Thread: Linking Data from CAD to QA

The foundation of such an integrated approach is the Digital Thread, which refers to the smooth flow of information that links all stages of the product life cycle. Starting from the CAD system to CAM programming and ending at quality inspection, all information necessary has been incorporated into an integrated system.

- Sustaining Process Consistency

The Digital Thread ensures that all prototyping-verified optimum toolpaths, cutting conditions, and fixtureing solutions are accurately transferred and optimized during actual manufacture. The quality inconsistencies arising from either equipment or personnel differences are thereby ruled out, and “seamless transitions” are achieved.

- Facilitating End-to-End Traceability

For industries that require compliance with regulations, the Digital Thread offers an auditable record of parts. Certifications of materials, the results of inspections, and machine work can be traced back to a part lot or part number. Traceability makes it easy to pass an audit from regulatory authorities and is the basis of an effective supply chain.

Framework of Quality: Compliancy with International Norms

The integrity of a unified process relies on the quality of quality management. Adherence to a standard such as the ISO 9001 standard of a quality management system provides a structured manner in which the control of the process should take place. A company that is a partner in this respect guarantees a commitment towards the integrated process as a project in itself. It gives the client the utmost certainty about the cost, quality, and time of the project.

What is the significance of precision CNC machining in reaching micron accuracy for sensitive components?

Modern precision engineering can deliver high accuracies, including a tolerance of ±0.005mm, with the help of state-of-the-art multi-axis CNC machining. While 3-axis machining needs a number of setups, 5-axis CNC machining allows the cutting instrument to move towards the workpiece from any angle, or approaching it from any direction, in a single setup. This is important, especially for aerospace or medical models with complex shapes.

Several key technologies are involved in realizing such accuracy. For example, high-speed CNC machines perform complex tool paths with absolute accuracy and accuracy-compensated machining technologies to correct for heat build-ups that occur during machining to prevent size drift. Finally, high-quality metrology tools such as Coordinate Measuring Machines are required to enable verification of parts to ensure that each part satisfies demanding specifications.

The use of such technologies plays a vital role in high-risk sectors. In the case of CNC Machining Aerospace Parts, it provides assurance that the machined parts can withstand high-pressure and high-temperature conditions. Additionally, for Medical Device CNC Machining, it provides a guarantee that the parts will be biocompatible and a perfect fit. For an engineer, it is important to grasp the use of precision CNC machining custom parts for the respective industries.

Can Advanced Manufacturing Really Achieve Excellence and Sustainability Metrics Simultaneously?

The trend is being confirmed by advanced manufacturing to prove that sustainability and superior performance can actually go hand in hand and work in conjunction with each other. Practices that come under Sustainable Manufacturing are being incorporated right into the precision machining process with technologies such as “lightweighting.”

The key methods used by the company include topology optimization, where the components are designed to use the least material required for the same strength. Finally, the company has adopted methods for minimizing the impact on the environment, which include the use of efficient cutting methods and recyclable materials. Companies that comply with the Environmental Management Standard ISO 14001 will find it easy to meet the ESG criteria of its customers without affecting the performance of parts.

Digital management systems are important for sustainability. These platforms, which ensure optimal production planning, reduced scrap, and efficient logistics through simulations, make significant contributions toward reducing waste and energy consumption. Partnering with an entity that has complete online custom CNC machining services can, therefore, be an important move for maximizing performance and sustainability.

How Will AI and Robotics Shape the Future of Custom Part Manufacturing?

The Custom Parts future in manufacturing involves embracing Artificial Intelligence and robots in a move that will open the door for “lights-out” manufacturing. The artificial intelligence involved in Custom Parts manufacturing is beyond just automation but is focused on analyzing and determining maintenance schedules for machines even before a shutdown occurs.

The robotic automation involved does everything from material processing to packaging. This, aside from minimizing labor costs, has made it possible to have continuous production, 24/7, resulting in a significant improvement in production throughput, especially when it comes to large orders. The integration of AI and robotics is establishing a whole new efficiency standard in the Future of Manufacturing.

This technological shift opens the way for mass customization. AI systems are capable of handling tough production orders, which enables the effective production of smaller lots of custom products, in addition to mass production. This improves Industrial Automation by making supply chains more agile in order to effectively adjust to the dynamics of the market.

Conclusion

In today’s uncertain manufacturing environment, an integrated and data-driven model of precision manufacturing has become not only advisable but the only way to ensure competitiveness, risk management, and sustainable growth. The seamless transition from prototype manufacturing to volume manufacturing, made possible by partners with superior technical expertise and comprehensive quality processes, is the only way to unlock the power of smart manufacturing solutions.

Author Bio

The author of this topic of interest has in-depth knowledge in precision manufacturing, as well as in the use of advanced CNC technology to provide high reliability solutions. His company, JS Precision, has been certified in AS9100D, IATF 16949, ISO 13485, and ISO 9001:2015, working towards providing complete solutions, right from validation to manufacturing, to clients all around the world. If you are seeking a free industry-specific feasibility study report, consult our team of experts today.

FAQs

Q1: What is the usual lead time associated with precision CNC prototyping?

A: Lead times will vary depending on complexity, material, or total quantity produced. While regular components, if supplied by reputable vendors, may provide short prototyping cycles of 3-5 business days, complex ones may take 10-15 days. Early feedback from DFM analysis is essential.

Q2: How are custom CNC parts maintained in terms of quality and traceability in the medical industry?

A: Certifications such as ISO 13485 provide quality and traceability, where all processes are strictly controlled. The batches are assigned a distinct lot number, and all documentation with material certification and inspection reports are included for traceability.

Q3: What are the key factors that drive costs during CNC machining, and how may these be optimized?

A: The main cost drivers are part complexity (which affects machining time), material, and quantity. Optimal cost can be achieved by simplifying designs, avoiding tight tolerancing where not necessary, material choice, and use of DFM.

Q4: What are the main points of differentiation between 3-axis and 5-axis CNC machining?

A: 3-axis CNC movements involve moving the cutter in three directions – X, Y, and Z axes, and are usually accomplished in more than one setup. 5-axis movements involve two rotation axes, which enable the cutter head to move towards the workpiece in every possible direction in a single setup.

Q5: What can I do to prepare my CAD files for an accurate CNC machining quote?

A: Provide an uncluttered 3D CAD file in STEP format. Include a Draft view that describes critical dimensions, specifications, surface finish, and material. Functional data about the component goes a long way in acquiring appropriate DFM comments from the engineering team.