In current times when the logistics operation is very brisk, the utmost importance is placed on ensuring the product reaches its destination safely and sound. Sometimes, when products are transported and there are vibrations such as when one crosses a bump on the road, air turbulence, and then there is physical contact when people physically move things from one location to another, there is a possibility of it getting damaged—if it is a fragile item such as electronics, glassware, and ceramic products.Here is molded pulp packaging comes into play.

Made from recycled paper products, molded pulp packaging not only eliminates environmental issues but also has the functionality of absorbing and damping vibrations too. In this article, the ways and means of molded pulp packaging absorbing vibrations during shipping, important characteristics of the packaging material, and advantages of this packaging material against other packaging solutions would be discussed.

Understanding Molded Pulp Packaging

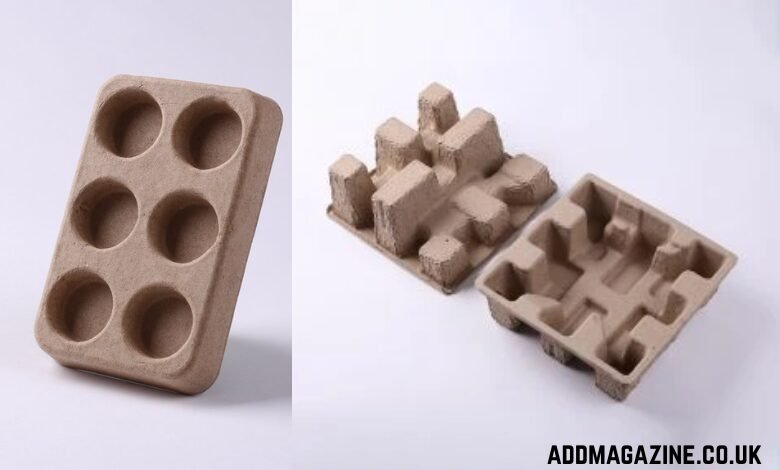

Molded pulp packaging, which you might also hear called molded fiber or pulp molding, is made by mixing recycled paper, cardboard, or other natural fibers with water to create a slurry. This blend is then shaped into custom forms using molds, dried, and sometimes pressed to enhance its strength. The end product is a lightweight, biodegradable material that’s often used for things like egg cartons, protective inserts for electronics, and shipping trays for fragile items.

What really sets molded pulp apart for shipping is its natural ability to withstand mechanical stresses. Unlike rigid plastics or foams, the fibrous structure of molded pulp can flex and bounce back, making it perfect for situations where things are constantly moving. Research has shown that molded pulp can effectively reduce G-forces and absorb vibrations better than many other options, all while taking up less space.

“Being 100% recyclable and made from renewable resources reflects a sustainable dimension of packaging requirements currently urged by consumers in terms of eco-friendly packaging.”

Examples of molded pulp packaging, in the form of protective inserts for recyclables, show the applicability of the process.

The Impact of Vibration in Transit

Vibration in transit is the vibrational movements that a product goes through when transported, either via truck, air transport, or ship. Vibration may range from low frequency, which may be felt when a vehicle hums on the road, to a high frequency when a product encounters potholes. This may result in failure or replacement.

Experts say that when products are subjected to constant vibrations, this would lead to weakening since items are prone to internal movement and stress accumulation. For example, products traveling a long distance would tend to move and rub against each other when not properly cushioned.

Effective packaging needs to absorb energy effectively, spreading it out over a larger area and longer time to reduce peak stresses. This is especially important for industries like e-commerce, where delicate items are shipped all over the world, and it also helps cut down on overall waste in the supply chain.

Key Properties of Molded Pulp for Vibration Resistance

The effectiveness of molded pulp packaging against vibration is also a result of a special material characteristic. The intersecting fibers produce a strong flexible material that can absorb shock and vibration. While hard materials fail under a shock by fracturing, pulp will compress and rebound.

Shock Absorption and Cushioning

Its ability to impact shock is one of the notable aspects associated with it. The fibrous structure and pores associated with it are naturally shock-absorbing, thus managing that impact and ensuring it is not transferable to the product. Tests have shown that molded pulp is better than others concerning shock and vibration, having passed drop and shock tests with ease. This is because it protects ceramics such as mugs from shock and drop effects by utilizing appropriately sized boxes.

The reason for this absorption is because of the compression and decompression properties similar to those seen in foam products but more eco-friendly. When exposed to moisture, molded pulp retains its properties well and absorbs vibrations without becoming too soft.

Structural Integrity and Durability

Even though molded pulp is lightweight, it boasts impressive structural strength. For instance, dry press molded pulp packaging is fantastic for cushioning delicate items, thanks to its fibers that interlock and create a sturdy barrier. Studies show that bleached chemi-thermomechanical pulp (BCTMP) types have a high Young’s modulus and break strength, surpassing recycled fibers in terms of mechanical properties.

This durability means molded pulp can handle repeated vibrations without falling apart, making it perfect for heavy-duty uses. Plus, its low density helps provide better insulation against temperature changes that could worsen vibration damage.

Design Features Enhancing Vibration Handling

Other than the materials, good design makes molded pulp resistant to vibrations. Specialized molds ensure a perfect fit with minimal motion in the package. Roll cradles or insert components with blocking and bracing features ensure a strong hold with minimal shifting during shipping.

Nestable designs provide a reduction in the volume of up to 50%, facilitating easy transport and maintaining protection. Depending on the requirement, such as the transport of wine, molded pulp has been used along with corrugated materials in order to provide better shock resistance. Such innovations help ensure that the product remains protected in high humidity routes.

Roll cradles composed of molded pulp demonstrate how design can hold cylindrical objects in place against the force of vibration.

Advantages of Molded Pulp Over Traditional Materials

When you stack molded pulp up against materials like EPS or wood, it really shines in terms of transit protection. It’s lighter, which helps cut down on fuel costs and emissions, while still offering shock and vibration absorption that’s just as good, if not better. Unlike those rigid foams that can crack when stressed repeatedly, molded pulp flexes, allowing it to absorb energy more effectively.

On the environmental front, it’s a clear winner: it’s fully biodegradable, recyclable, and crafted from waste materials, which helps tackle plastic pollution. Plus, its ability to nest means lower storage and shipping costs, and it can be tailored for different products. Sure, EPS might have the edge in insulation in some situations, but molded pulp’s moisture resistance and overall durability make it a top choice for many delicate items.

Real-World Applications and Case Studies

In application, molded pulp is used to protect anything from mugs to electronics. For example, firms packaging ceramics use it to protect against shock by reducing breakages. Wineries use it together with corrugated material to provide tough packaging solutions, testing successful under drop, compression, and vibration tests.

“In the industrial sectors, there is an application of molded pulp replacing wood and foam in heavy-duty packaging, providing sustainable solutions without losing protection. There is an average of more than 50% reduction in damaged products as well.

Conclusion

Molded pulp packaging is a clever step forward in managing vibrations during transit, combining excellent protection with a commitment to the environment. Its fiber-based structure effectively absorbs and dampens impacts, ensuring that products can withstand the challenges of shipping.

For businesses, switching to molded pulp means reduced costs, meeting sustainability targets, and keeping customers happy with undamaged deliveries. As more industries embrace eco-friendly options, molded pulp emerges as a dependable choice for packaging that resists vibrations. Whether you’re in e-commerce or manufacturing, considering this material could really enhance your shipping strategy.