In high-volume manufacturing, speed is often treated as the primary lever for improving output. Cycle times are compressed, shifts are extended, and equipment is pushed closer to capacity. On paper, these changes promise higher throughput. On the plant floor, the results are often less predictable. Output may increase briefly, but quality variation, rework, and coordination problems tend to surface soon after.

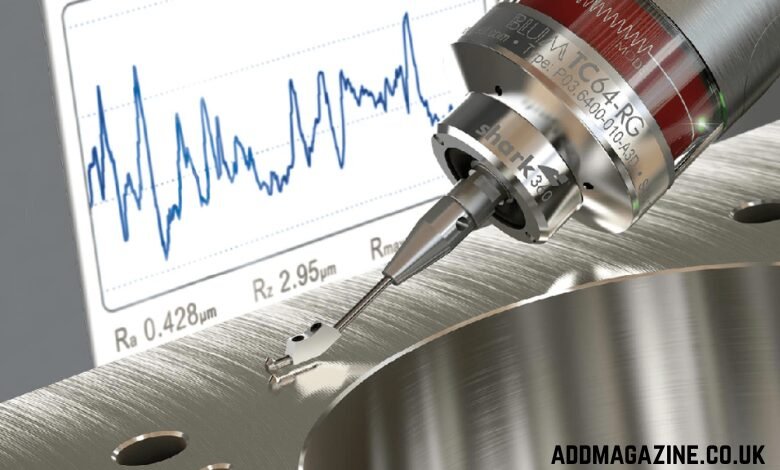

Surface finishing sits at the center of this tension. It is one of the final processes to touch a part before inspection, assembly, or shipment. When finishing becomes inconsistent, the effects ripple across the production line. What slows manufacturing is rarely that finishing is too slow, but that its results vary. In high-volume environments, consistency protects throughput more reliably than incremental gains in speed.

Surface finish consistency as an operational stabilizer

Surface finish consistency refers to producing parts with uniform functional and visual characteristics across batches, shifts, and operators. This includes edge condition, texture uniformity, and the absence of defects that affect handling or performance. In operations that rely on vibratory plating services, consistency is often assumed once a process is established. In practice, maintaining it becomes more challenging as volume increases and product mix expands.

When finishing output is predictable, downstream processes operate with less hesitation. Assemblers handle parts confidently, inspectors apply standards quickly, and planners rely on expected flow. Speed-focused optimization, by contrast, tends to overlook how variation compounds across the system.

Why consistency reduces hidden delays

Inconsistent surface finish introduces friction that rarely appears in production metrics.

- Operators adjust handling technique from part to part

- Inspectors spend additional time interpreting acceptability

- Parts are rerouted unexpectedly for reprocessing

These delays may seem minor individually, but at scale they erode throughput steadily.

Speed gains often shift problems instead of removing them

Increasing finishing speed can improve local output while degrading system-level performance. When cycle times are shortened without equivalent control over finish quality, defects and variation increase. Those issues are then absorbed elsewhere in the line, typically at inspection or assembly.

In high-volume environments, even small increases in defect rates translate into significant rework and congestion downstream.

The illusion of faster throughput

Speed improvements can mask growing instability.

- Finished parts accumulate while awaiting inspection clearance

- Assembly lines experience intermittent shortages

- Overtime is used to recover lost capacity

From a reporting standpoint, output may look acceptable. Operationally, variability is doing the damage.

Inspection behavior changes when finish is inconsistent

Inspection is often the first area to feel the effects of surface variation. When finishes are uniform, inspectors apply standards quickly and confidently. As variation increases, inspection becomes interpretive. Decisions slow, borderline cases increase, and escalation becomes more frequent.

This behavioral shift directly affects flow.

How inspection absorbs finishing variability

Inspection acts as a buffer for upstream inconsistency.

- Time per part increases without formal process changes

- Queues form even when staffing levels remain unchanged

- Release timing becomes unpredictable

These effects are difficult to trace back to speed-driven decisions made earlier.

Assembly efficiency depends on predictable surface condition

Assembly processes assume a certain level of finish consistency. Parts that feel different, fit unevenly, or carry minor surface defects require more careful handling. Operators slow down to avoid damage or misalignment.

In high-volume settings, this caution compounds quickly.

Assembly slowdowns caused by finish variation

Inconsistent finish disrupts work rhythm.

- Slower part loading and alignment

- Increased pauses to verify surface condition

- Higher likelihood of cosmetic damage during handling

None of these issues are resolved by faster finishing upstream.

Rework becomes normalized when speed is prioritized

When finishing is optimized for speed, rework often becomes an accepted cost. Parts are quietly reprocessed to correct surface issues, consuming capacity without being flagged as exceptions. Over time, this rework blends into normal output.

This normalization hides the real cost of variation.

The capacity impact of quiet rework

Untracked rework undermines true throughput.

- Machine time is consumed without increasing shipped volume

- Labor effort rises without visible gains

- Scheduling assumptions drift away from reality

Consistency reduces the need for rework far more effectively than speed reduces cycle time.

Consistency supports better planning and staffing decisions

Predictable finishing outcomes allow planners to rely on expected flow. When finish quality is stable, downstream processes can be staffed and scheduled with confidence. When variability is high, planning becomes defensive, relying on buffers and overtime.

High-volume manufacturing depends on repeatability more than peak speed.

Planning benefits of consistent finishing

Stable output enables steadier operations.

- Fewer last-minute staffing adjustments

- Reduced dependence on safety stock

- More accurate daily output forecasts

These benefits compound over time.

Equipment utilization improves with consistent processes

Inconsistent finishing often leads to stop-start behavior. Equipment waits for rework, inspection clearance, or downstream availability. Utilization drops not because machines are slow, but because flow is interrupted.

Consistency smooths these interruptions.

How consistency protects utilization

Predictable finishing keeps equipment engaged.

- Fewer unplanned pauses between cycles

- Reduced need for repeat runs

- Better alignment with downstream capacity

Speed alone cannot achieve this alignment.

Throughput is a system outcome, not a local metric

Throughput reflects how well processes interact, not how fast individual steps operate in isolation. Industrial engineering emphasizes flow stability and constraint management over local optimization. A general explanation of this system-based view is outlined in Wikipedia’s overview of industrial engineering, which describes how interaction between processes shapes overall output.

From this perspective, consistent surface finishing supports throughput by stabilizing interactions across the production line.

When speed matters—and when it does not

Speed is not irrelevant. In stable, well-controlled processes, reducing cycle time can improve output. The problem arises when speed is pursued before consistency is secured. In high-volume environments, variability overwhelms small speed gains.

The sequence matters.

- Consistency establishes predictable flow

- Predictability enables reliable planning

- Speed improvements then compound rather than disrupt

Reversing this order undermines throughput.

Closing perspective: consistency as a throughput multiplier

In high-volume manufacturing, the instinct to push for speed is understandable. Output targets are visible, and cycle time reductions are easy to measure. Surface finish consistency works quietly. Its benefits appear as fewer interruptions, steadier pacing, and reduced rework.

For operations that depend on surface finishing, prioritizing consistency creates a foundation for sustainable throughput. Speed applied on top of that foundation strengthens performance. Speed applied without it shifts problems elsewhere. Over time, manufacturing lines move more product not by rushing individual steps, but by ensuring each step behaves the same way, every time.