Risk assessments play a crucial role in ensuring the effectiveness of any safety management system. They help identify and evaluate potential risks in the workplace, estimate probability of harm or damage, and implement measures to control or minimize such risks. But who does it all? In this article, we are going to run through all you need to know about risk assessments and who does what when it comes to doing them.

Who is Responsible for Conducting a Hazard Assessment ?

Employers are required to perform hazard assessments. They are legally bound to develop safe working environments for their employees. This entails the detection of hazards and actions to minimize or eliminate them. The significant roles of employers include hazard assessment, taking action, and employee training.

Employers must conduct hazard assessments, but it is not their responsibility to do so. For instance, the boss of a factory may instruct an employee or outsource the hazard assessment to a third party. Whoever conducts the assessment is known as the competent person.

Following the determination of hazards, the employer, competent person, and workers must take action immediately. This can involve the issuing of personal protective equipment (PPE), personal protective equipment (PPE) training employees in ergonomics, and the installation of emergency kits containing fire blankets, fire sprays, and first-aid kits. onomics, and maintenance schedule.

Employers are also required to make workers aware of potential hazards in the workplace. For instance, if a new machine is introduced to a factory, the company has to train employees to operate it safely.

The basis on which hazard assessments are made is not factual information. The OSH Act of 1970 sets employers to a level of safety, e.g., reducing safety and health hazards. They cannot do so without hazard assessments.

Even though employers and competent persons bear the heaviest responsibility for performing hazard assessments, employees also play an important role in making the workplace safe. First of all, employees are required to report any hazards they notice. If an employee notices a burst pipe, they should report it to their supervisor.

Workers are also required to go for safety training. For example, an understanding of the risks and dangers of fire is required in order to keep everyone safe in a foundry. In addition, workers are also required to follow safety protocols and utilize PPE as and when required. If a company provides welding fire protection gloves, workers are required to wear them during work. When fire-related incidents still happen despite preventative measures, specialized restoration services focused on fire damage portland or play a key role in helping facilities recover and return to safe operation.

In the end, it is a mutual effort by the employer and employee to safeguard the workplace. Employers have the responsibility of seeing that hazard evaluation is done and actions are taken when necessary. Employees, however, are responsible for receiving safety training, wearing PPE when necessary, and reporting seen possible hazards on the job.

Importance of Risk Assessments in Various Industries

Risk assessments are extremely important across most industries, from construction and manufacturing to healthcare and education. In construction, for example, risk assessments are used to identify risks like falling off heights, electrical shock, or getting hit by falling objects. By implementing control measures like hard hats, safety harnesses, and guardrails, employers can reduce the likelihood of accidents and injuries.

In the health care field, Hazard Identification and risk assessment are both important in creating harmany in the organization. Risk assessment is used in the identification of potential hazards such as contact with infectious disease, slips and falls, and workplace violence. Control measures such as personal protective equipment, hand hygiene, and security controls can be implemented to reduce injury to workers and patients.

Similarly, in the education industry, risk assessment is utilized to identify hazards such as violence, falls, and exposure to dangerous chemicals. By implementing control measures such as non-slippery floors, ventilations, and security, schools can ensure it becomes safer for teachers and students.

Generally, risk assessments are an asset for organizations and companies to guarantee their employees’ health and safety. Through hazard identification and control measures, employers reduce the chances of accidents, injuries, and other types of harm, ensuring a safer and more productive work environment.

Steps in Conducting a Risk Assessment

Risk assessment is an important step toward the assurance of occupational safety. By identifying possible hazards and assessing the risks associated with them, employers can take preventive measures to prevent accidents and injuries

The following are some additional details about each phase of the risk assessment process:

1. Identifying Hazards

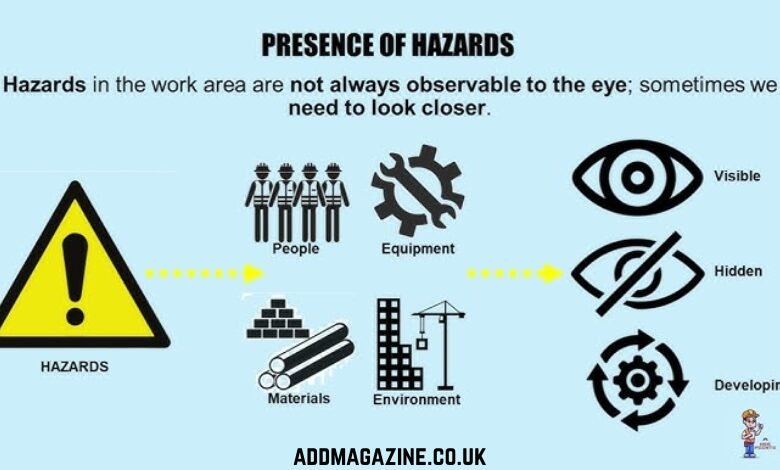

While identifying hazards in the workplace, all corners of the work environment need to be considered. It can include physical hazards such as equipment and machinery, chemical hazards such as exposure to toxic chemicals, biological hazards such as exposure to infectious diseases, and ergonomic hazards such as bending postures or repetitive movements. It should also be considered any potential hazards that can be created by the work environment itself, such as poor lighting or ventilation.

One good technique for identifying hazards is to conduct a walk through around the workplace, looking for anything that is most likely to cause a hazard and recording it. It is also a good idea to talk to employees and ask them to give their views on any potential hazards they have identified in their work.

2. Assessing the Risks

When there are identified hazards, it must be assessed on what risk each of them poses. This can involve considering the likelihood of harm to occur, the extent of harm that would occur, and the resulting consequence for each hazard. For example, a high-risk hazard to occur which would result in severe harm may deserve greater priority than a lower-probability hazard to occur which could result in negligible harm.

It is also required to quantify any factors that can increase or decrease the risks concerning a hazard analysis. For example, wearing protective clothing may reduce the risks of an unsafe activity, while inadequate training or inexperience may increase the risks.

3. Putting Control Measures into Place

Once risks have been found, controls must be implemented to reduce or eliminate the identified hazard. This can take many different forms, such as engineering controls such as physical barriers or ventilation systems, administrative controls such as training or new procedures and policy, and personal protective equipment such as gloves or respirators.

It must be ensured that any control measures that are put in place are monitored and maintained to ensure that they remain effective. It might involve regular equipment checks or training sessions to ensure that they are being properly applied.

4. Monitoring and Reviewing the Risk Assessment

Finally, there should be constant monitoring and examination of the risk assessment procedure to determine perpetual security within the workplace. This could involve regular reassessment of the working environment and any potential risks, and regular examination of the effectiveness of any implemented control procedures.

It is also important to remain up to date with any regulatory or industry standard updates that may influence the risk assessment process. This can help with the assurance that the risk assessment works and complies with any requirements that may apply.

Conclusion

In conclusion, risk assessments are critical to ensuring a safe working environment and reducing liability for businesses. Employers must carry out risk assessments, but health and safety experts and workers also have a significant role to play. Using the steps mentioned above, businesses can successfully identify hazards, evaluate risks, and implement control measures, which ultimately lead to a safer work environment for employees.