Repmold refers to a specific type of mold used in the process of injection molding, a manufacturing technique commonly employed in industries such as automotive, electronics, medical devices, and consumer goods. The term Repmold is often associated with high-quality, precise, and efficient molding solutions. These molds are designed to produce plastic or metal components with high accuracy and in large volumes. Repmold plays a critical role in ensuring the creation of parts that meet both aesthetic and functional requirements while maintaining cost-effectiveness.

This blog post provides a detailed look at Repmold, discussing what it is, its uses, the manufacturing process, types of materials used, advantages, and challenges. If you’re considering using Repmold for your manufacturing needs, this guide will offer useful insights into the technology, how it works, and what it can offer.

What is Repmold?

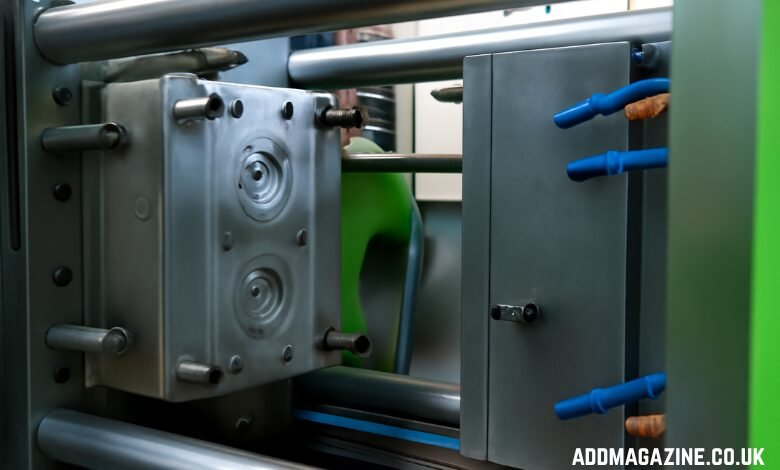

Repmold refers to a precision-crafted mold used in the injection molding process, where molten material is injected under high pressure into a mold cavity. Once the material cools, it hardens, taking on the mold’s shape. Repmold molds are typically designed for high-volume production runs, producing parts with tight tolerances and high precision.

In the injection molding process, the material can be a variety of substances, including plastics, metals, and composites. Repmold is often used when there is a need for quick production of parts with consistent quality. The primary application of Repmold is in industries that require mass production of identical parts or products with high efficiency.

How Does Repmold Work?

The process of creating a part with Repmold is relatively straightforward but requires precision and careful control over various parameters. Here’s a breakdown of how the Repmold injection molding process works:

- Design and Creation of Mold: The process begins with designing the mold. Repmold tools are made to exact specifications, often based on a CAD (Computer-Aided Design) model. The design will consider the shape, size, and tolerances needed for the part to fit into its final product assembly. Once the design is complete, the mold is manufactured, typically from high-strength steel or aluminum.

- Material Injection: Once the mold is set, the next step is to inject molten material into the cavity, where it fills the space and begins to solidify as it cools. This material could be plastic, metal, or a composite. In the case of plastic molding, materials like polyethylene, polypropylene, and PVC are commonly used.

- Cooling and Solidification: Once the material is injected into the mold, it is allowed to cool and solidify. This cooling process is vital for ensuring that the material retains its shape and strength. The time required for cooling depends on the material used and the complexity of the part being produced.

- Ejection: Once the material has cooled and solidified, the mold is opened, and the finished part is ejected from the mold. The ejection process is automated, and the part is removed without causing damage to the mold.

- Post-processing: In some cases, the molded part may require post-processing steps, such as trimming, painting, or adding other finishing touches. These steps are done to ensure that the part meets the required functional and aesthetic standards.

Advanced Injection Molding Processes in Repmold

- Multi-material Injection Molding: Different materials are injected simultaneously or in stages, allowing the creation of parts that combine multiple material benefits (e.g., flexibility, strength, wear resistance).

- Micro Injection Molding: Focuses on producing extremely small components with high accuracy, ideal for applications in electronics and medical devices.

- Gas-Assisted Injection Molding: Uses gas injection to reduce material usage and cycle times, making it suitable for large and complex automotive parts.

- Stacked Injection Molding: Involves multiple injection units stacked on top of each other to create parts with different layers or materials, improving efficiency and reducing production time.

- Overmolding: A process where a soft material (like rubber) is molded over a hard material (such as plastic or metal), allowing for improved grip, sealing, and aesthetic appeal, often used in automotive and consumer products.

- Injection Compression Molding: Combines the standard injection molding process with compression to produce parts with less residual stress, improving part quality and precision.

- Injection Molding with Inserts: Allows for the integration of metal or plastic inserts into the molded plastic parts, adding strength and functionality, commonly used in automotive and electronics.

Materials Used in Repmold

Repmold can be used with a wide range of materials, each offering specific properties suited to different applications. The choice of material is a crucial factor in the injection molding process, as it directly affects the performance, durability, and cost of the final product. Here are some of the most common materials used in Repmold processes:

- Plastics: This is the most common material used in injection molding. Plastics are highly adaptable, affordable, and can be shaped into intricate forms, making them a popular choice for a variety of applications. Some commonly used plastics in Repmold include:

- Polypropylene (PP): Known for its low density and resistance to chemical and heat degradation, making it ideal for automotive and packaging components.

- Acrylonitrile Butadiene Styrene (ABS): A strong plastic that is commonly used in the automotive, electronics, and consumer goods industries.

- Polyethylene (PE): Used for products that need to be flexible and resistant to impact, such as bottles, toys, and packaging materials.

- Polycarbonate (PC): Known for its high strength and optical clarity, making it ideal for optical lenses, automotive parts, and medical devices.

- Metals: While plastics dominate in injection molding, metals can also be used in certain molding processes, especially for parts that need to withstand high temperatures or provide added strength. Some of the metals used in Repmold include:

- Aluminum: A lightweight and durable metal used in applications where weight is a concern, such as in the automotive and aerospace industries.

- Stainless Steel: Known for its resistance to corrosion and high strength, stainless steel is commonly used for making medical, industrial, and food-processing equipment.

- Composites: Composites, such as fiberglass-reinforced plastic, are used when parts need to have a higher strength-to-weight ratio. These materials are typically used in aerospace, automotive, and military applications.

Advantages of Using Repmold

There are several key benefits of using Repmold for mass production. These advantages make Repmold a go-to choice for industries requiring high-volume production with high precision:

- Cost Efficiency: One of the primary advantages of using Repmold is cost efficiency. The injection molding process allows for the mass production of identical parts, which means that unit costs decrease as production volume increases. This makes it ideal for industries that need to produce large quantities of parts while keeping costs down.

- High Precision and Consistency: Repmold molds are designed to produce parts with tight tolerances and high precision. This is especially important in industries like automotive and medical devices, where even the slightest deviation in part dimensions can have serious consequences.

- Speed of Production: Repmold can produce large volumes of parts in a relatively short amount of time. This rapid production speed is especially beneficial in industries where quick turnaround times are essential.

- Flexibility: Repmold molds can be designed for a variety of part shapes and sizes. This flexibility makes them useful across a wide range of industries and applications.

- Complex Geometries: Repmold is capable of creating parts with complex geometries that may be difficult to achieve with other manufacturing techniques. This makes it ideal for industries that require intricate designs or parts with multiple components.

- Low Material Waste: Injection molding is an energy-efficient technique that helps reduce material wastage by utilizing the exact amount needed for each part. The materials are injected into the mold, and excess material is often reused, helping to reduce production costs and environmental impact.

- Durability and Strength: Parts made using Repmold, especially those made from metal or reinforced plastic, tend to be durable and strong. This makes them suitable for applications in harsh environments, such as automotive parts and industrial components.

Challenges of Repmold

While Repmold has many advantages, it also comes with its own set of challenges that need to be considered:

- High Initial Setup Costs: The design and creation of Repmold tools can be expensive. The initial cost of creating a mold, particularly for intricate designs, can be considerable. However, these costs are offset over time as the volume of production increases.

- Limited Flexibility in Small Batches: Although Repmold is well-suited for mass production, it is not always ideal for small batch runs. The initial setup time and cost may not justify the production of a small number of parts.

- Material Limitations: While Repmold can work with a wide variety of materials, some specialized materials may require different processes or tooling. This could limit the range of materials that can be used for certain applications.

- Mold Wear: Over time, the molds used in the Repmold process can wear out due to repeated use. This can affect the quality of the parts produced and may require the molds to be replaced or repaired periodically.

Industries That Benefit from Repmold

Repmold is employed in multiple sectors that demand mass production of parts with precise material characteristics. Some of the key industries that benefit from Repmold include:

- Automotive: In the automotive industry, Repmold is used to produce a wide range of parts, from interior components to engine parts and structural elements. The ability to create lightweight yet durable parts makes it a popular choice.

- Medical Devices: Repmold is used in the production of medical components that need to meet stringent regulatory standards. Parts like syringes, diagnostic devices, and surgical tools can be made using Repmold.

- Consumer Goods: Many consumer goods products, such as toys, appliances, and packaging materials, are produced using the Repmold process. The ability to mass-produce these products efficiently is essential to keeping costs low for consumers.

- Electronics: Repmold is widely used in the production of electronic components, such as housings, connectors, and connectors, which require high precision and strength.

- Aerospace: The aerospace industry uses Repmold to manufacture lightweight but durable components, such as engine parts and structural components, where material strength and weight are critical.

Conclusion

Repmold is a key technology in the world of injection molding. This process enables manufacturers to create components with exceptional accuracy and speed, making it perfect for industries that need high-volume production with exacting specifications. The ability to use a wide range of materials, from plastics to metals, further enhances its versatility. While the process comes with certain challenges, such as high initial costs and limitations for small batch runs, its benefits in terms of cost efficiency, speed, and consistency make it an essential part of many modern manufacturing industries. Whether you are in automotive, medical, electronics, or consumer goods manufacturing, understanding the Repmold process can help you make informed decisions about the best way to produce your products.