Manufacturing has entered an age where openness is no longer optional. Modern consumers are informed, socially aware, and quick to question how products are made. They expect clarity on sourcing, environmental impact, and labour conditions. A company’s reputation now depends as much on how it operates as on what it sells.

In the past, many manufacturers operated behind closed doors, sharing little about their processes. That approach is no longer sustainable. A lack of information can easily raise doubts and damage public confidence.

When people can’t see how things are made, they start to wonder what’s being hidden. Transparency helps bridge that gap, assuring customers that what they buy aligns with their values.

This article explores many such reasons that make transparency in the manufacturing industry a necessity.

Strengthens Relationships with Consumers and Partners

Transparency works best when it’s proactive. Sharing information about sourcing, quality control, and environmental practices allows companies to build stronger relationships with their audiences.

Consider the example of sustainability demand. A PwC survey found that consumers care about sustainability. And they are willing to back it up by paying 9.7% premium costs for sustainable products. Moreover, they want to do so despite the increasing inflation and cost of living.

However, a Wiley Online Library study says that trust in eco-labels is declining. There is a wide range of eco-labels that manufacturing companies can use. Some of them can even be uncertified. Thus, there is a lack of trust, which is not enough to convince customers to buy sustainable products.

People want brands they can trust, and it grows when companies show how they meet standards rather than just claim they do. Open communication also helps businesses stay in control of their narratives.

A World Economic Forum article claims that storytelling is the key to success for businesses in today’s disruptive era. It has been an age-old practice that dates back to cave drawings. Transparent updates, whether about production changes, recalls, or sustainability goals, show responsibility and build resilience in public perception.

Why does supply chain transparency matter to business partners?

Business partners rely on transparent information to assess reliability and risk. When a manufacturer shares sourcing details, certifications, and compliance records, it builds mutual confidence. This openness leads to stronger collaborations, fewer disputes, and smoother operations since all parties can verify that ethical and quality standards are met.

Prevents Costly Mistakes and Rebuilds Trust

Honesty in communication doesn’t just protect a company’s image; it is also a duty of manufacturers. This is especially true if the product can pose a significant threat to the user.

Transparency became a major topic of discussion after several high-profile product failures exposed the risks of poor disclosure. Some companies were found to have known about defects but failed to communicate them clearly, leading to lawsuits, recalls, and public backlash.

The healthcare and medical device industries, in particular, have faced intense scrutiny for how they handle product safety. Consider the example of transvaginal mesh lawsuits. According to TorHoerman Law, patients use the product to treat pelvic organ prolapse or stress urinary incontinence.

However, some patients have complained about a manufacturing defect. They say that the mesh is prone to breaking during removal. This can lead to severe consequences like pain, infection, organ perforation, vaginal scarring, and more. Thus, they have filed lawsuits against manufacturers, including Ethicon, C.R. Bard, Coloplast, and others. They are waiting for the transvaginal mesh settlement amounts to be paid to cover their expenses and damage.

Manufacturers in every sector can learn from this. Transparency prevents confusion, limits misinformation, and allows companies to address issues before they spiral. It turns accountability into a strength rather than a weakness.

How do manufacturers regain credibility after a transparency failure?

Rebuilding trust takes time and consistent effort. Companies can start by admitting past mistakes, compensating affected parties, and implementing new accountability measures. Regular updates, third-party audits, and open communication channels show a genuine intent to change. Gradual honesty restores confidence more effectively than empty statements or rebranding attempts.

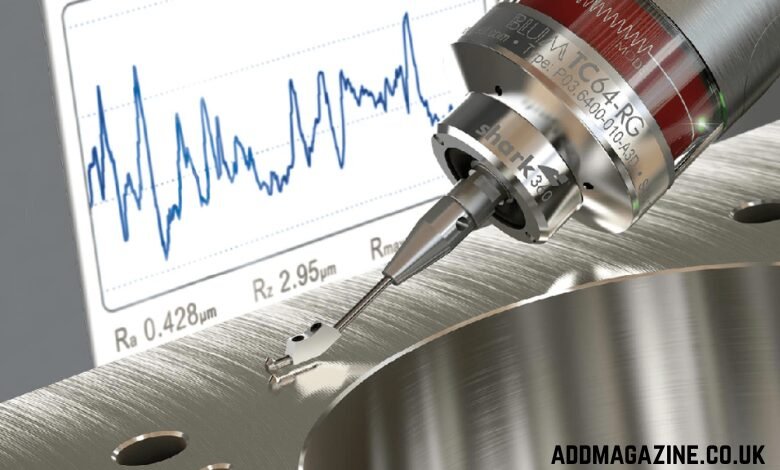

Improves Efficiency and Accountability Through Technology

Modern tools make openness more achievable than ever. Blockchain systems, smart sensors, and digital tracking can verify each step of production, from sourcing raw materials to final delivery. These tools don’t just support compliance; they create a shared sense of accountability throughout the supply chain.

An IEEE Xplore journal study proposes a similar blockchain-based solution that can improve transparency and efficiency in Manufacturing-as-a-Service (MaaS) supply chains. The solution can help address problems like centralisation, data tampering, and communication delays found in traditional systems.

It introduces a master-slave multi-chain data storage model along with a new consensus algorithm called Service Quality Scoring Based Practical Byzantine Fault Tolerance (SQS-PBFT). Experimental results show significant performance gains, including reduced communication overhead, lower latency, higher throughput, and fewer malicious activities. This makes it a more efficient and secure approach for managing transparent MaaS supply chains.

With real-time data and accessible reporting, teams can spot inefficiencies early, fix issues faster, and make informed decisions. Transparency, in this sense, improves performance. It transforms ethical responsibility into an operational advantage, something that strengthens the entire manufacturing process.

What role does artificial intelligence play in promoting transparency in manufacturing?

Artificial intelligence helps manufacturers monitor performance, detect errors, and predict maintenance needs. This data can be shared to show compliance and operational honesty. AI-driven analytics make reporting more accurate and accessible, allowing stakeholders to understand production processes without relying solely on self-reported information.

Builds Long-Term Stability and Loyalty

Being open may seem risky because it exposes flaws or challenges, but the long-term rewards far outweigh the discomfort. Companies that practice transparency attract more loyal customers, gain investor confidence, and maintain stronger relationships with employees.

According to a ScienceDirect study, consumers are increasingly portrayed as demanding brand transparency. Moreover, researchers have found that around three-quarters of customers are even willing to switch to a company that prioritises transparency. It becomes salient when related to decision-making risk and personal relevance.

As regulations become stricter and public scrutiny intensifies, transparency acts as both a shield and a strategy. It protects against compliance failures and builds a brand identity grounded in integrity. In the long run, transparency isn’t a marketing angle; it’s a sustainable business model.

Transparent practices also encourage continuous improvement within organizations. When data about performance, efficiency, and sustainability is shared openly, teams can identify gaps more accurately and collaborate to solve them. This openness transforms accountability into innovation, pushing manufacturers to adopt better processes and technologies.